Handheld CNC Router

1/23 - present

Skills utilized:

Electromechanical design (sensing and actuation)

Programming (C++)

Microcontroller use and custom electronics

CAD (Fusion 360)

Digital fabrication (waterjet, metal laser cutting, 3D printing)

Rigid body dynamics

Awards and Recognition:

ASME’s Electromechanical Design/Electronics and Controls Award for Mechatronics capstone course (Spring 2023)

Accepted to exhibit at Open Sauce (2023 and 2024)

Created along with the pleasure of Sonya Guralnyk, Jobanpreet Mutti, Sanzhar Abatov, and Hans Baschy.

Patent Pending

Compass Handheld CNC Router © 2024 is licensed under CC BY-NC-SA 4.0

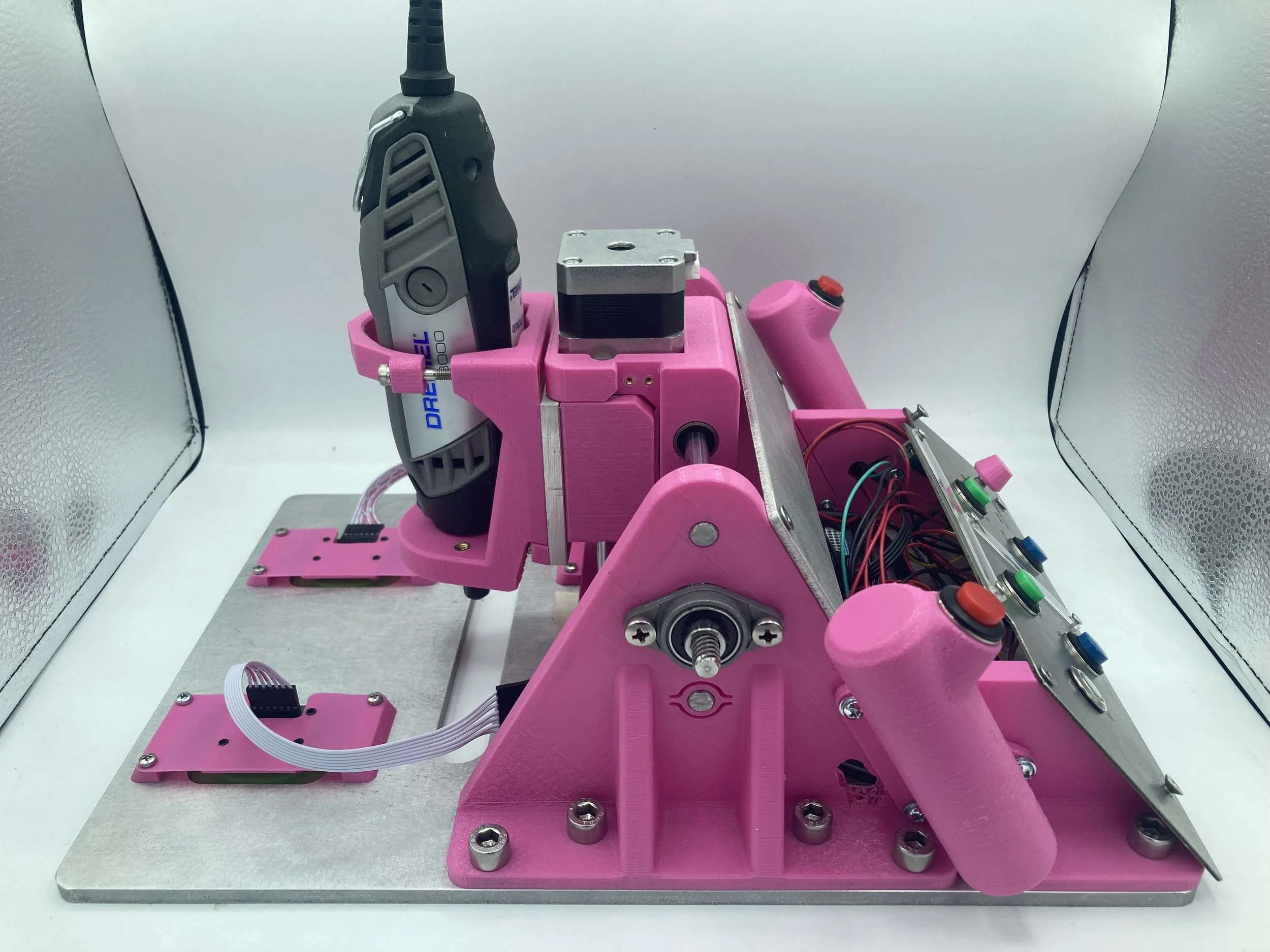

I’ve made a Handheld CNC Router that allows you to create precise 2D cuts on the go. Users manually guide the device along a pre-programmed path while the spindle moves to stay precisely on it. This is accomplished using embedded sensors to determine the router’s position, while the spindle is actuated accordingly along the gantry with stepper motors. The purpose of the product is to replace a traditional CNC machine, being more portable and allowing a more flexible working space (i.e. you could cut stock like a wooden floor that would be impossible to put on a CNC bed). This device also gives people with conditions like Parkinson’s the ability to do hands on woodworking again, seeing to it that their condition doesn’t impair their ability to make precise, beautiful creations.

Unlike other solutions that use external markers and sensors to locate the router, all of the positioning comes from optical flow sensors embedded in the device - the same sensors you would see on computer mice. This makes usage more seamless, allowing for precise machining without the need for setup beforehand. The workflow is as simple as the user uploading the desired path to be cut, zeroing the device with the click of a couple buttons, then simply moving the router along the material. The drill position is then sensed and corrected so that the final result is a perfect cut even if the user slips or rotates the router incorrectly.

Demo of straight-line drawing for final showcase. Users can move the device in any direction, speed, and orientation, and the drawn line still remains straight.

Sine wave testing

The main components of the assembly include a 3D printed body, aluminum waterjet base, 4 optical flow sensors, and 2 stepper motors coupled with lead screw gantries for actuation in two dimensions. All sensing, actuation, and control are handled with a single Teensy 4.1 microcontroller. Limit switches were implemented on both axes for homing the device. The main user inputs are two buttons that must be held down at all times when running (this ensures that the user in control of the device at all times. Otherwise everything stops immediately and the cutting bit is raised out of the workpiece). The homing and UI buttons can be seen in the figure to the right.

Main Components

Physical architecture of the device

Spring mounts to ensure reliable readings from the sensors

Manufacturing

The hardware consists of 3D printed parts, a 1/4” waterjet aluminum base, laser cut sheet metal panels, optical flow sensors, and stepper motors that are all integrated using linear motion parts, nuts, bolts, and heat set inserts. The linear motion parts were first put together by my group-mates so that we could test the stepper motors. I’m glad we did this early on, because the stepper motor development was very buggy and time consuming.

The first sensor tests were actually me taking apart old computer mice and “hacking” the values from their sensors. This was a nice proof of concept to make sure that this method of sensing could work. I 3D printed a sled for the sensor too so that I could run it in a track of an exact distance and determine the quality. Even with decades old mice, the readings were still relatively precise and repeatable, so we decided to move forward with more expensive sensors. After I got the new sensors working individually, I made a jig to test 4 sensors together. This was used to check how well position and orientation measurements were tracked.

After all the parts were tested and working individually, the CAD was done, and the parts were printed, everything was assembled.